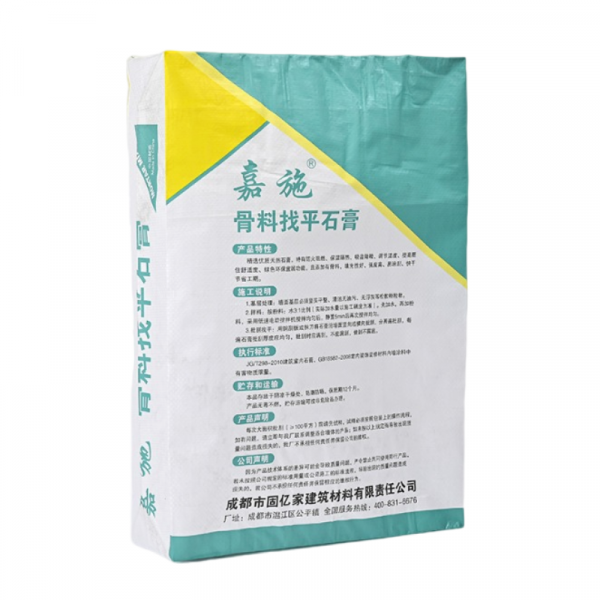

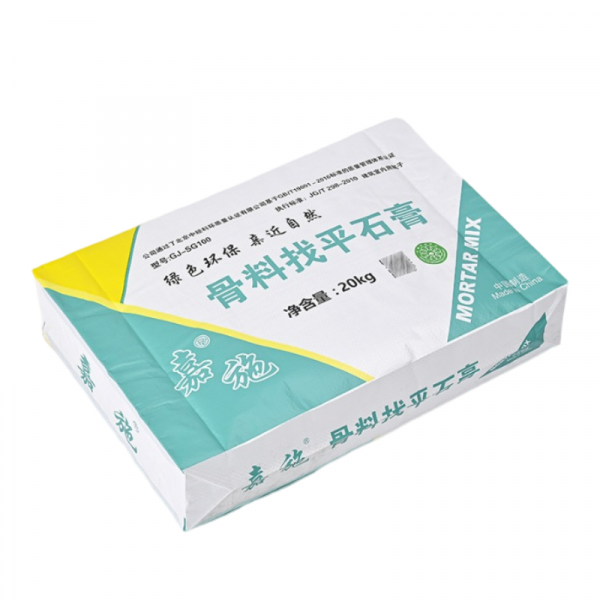

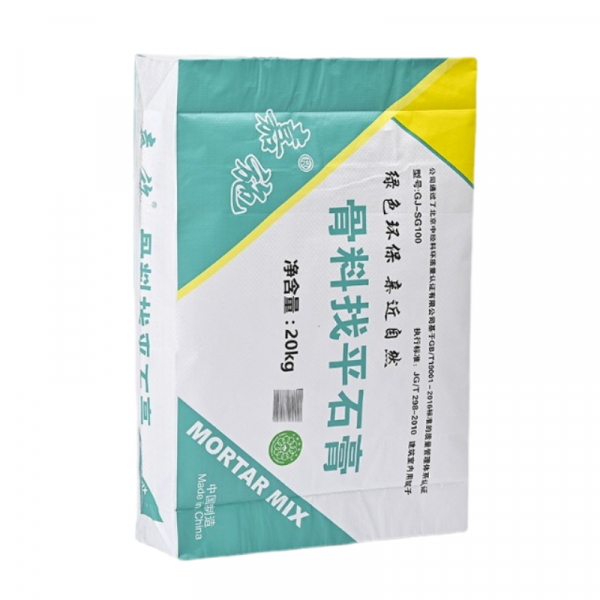

Kraft paper woven bag-Gypsum powder packaging bag

This gypsum powder packaging bag is a kraft paper woven bag with an outer layer of kraft paper. The kraft paper is very beautiful, more three-dimensional, more neatly placed, and the woven bag has good load-bearing performance.

Gypsum powder has many applications

1. Building materials and construction

a: Anhydrite cement and cementitious materials: Anhydrite cement or cementitious materials can be produced by adding an appropriate amount of activator, which is suitable for the reinforcement of soft soil foundations, wall painting, mechanical models, tunnel support and the production of fiber pressure plates, etc. .

b: Used as co-solvent and purifier in glass production process.

c: Used as filler in industrial production of plastics, rubber, coatings, asphalt, linoleum, etc.

d: The main raw materials of concrete expansion agent, anti-cracking agent and self-leveling mortar.

e: Cast-in-place piles and deep mixing piles are used as large expansion materials to increase friction.

f: Used as composite mineralizer in the production of special cement

2. Chemical industry

a: Produce sulfuric acid and produce light cement as a by-product.

b: Produce ammonium sulfate, with light calcium carbonate as a by-product.

3. Agriculture

a: Improve soil, adjust pH, suitable for improving soils such as saline-alkali soil and red soil.

b: Used as calcium and sulfur complex mineral fertilizer in edible fungus cultivation to adjust the pH of the culture medium.

c: Used as a complex mineral feed additive in poultry and livestock feed.

Anhydrite powder is packed in plastic woven composite bags with a specification of 50±1Kg, and can be packaged in bulk and other specifications according to user requirements.

Anhydrite powder should be stored in ventilated and dry conditions.

4. Cathodic protection

Used as one of the packing materials for sacrificial anodes. The general ratio is as follows: 75% gypsum powder, 20% bentonite, and 5% sodium sulfate.